With the expertise of our professional team of executives, along with efficient production process and rich experience in world-class production, the Oriental Garment Co., Ltd. can guarantee on-time merchandise delivery through the implementation of the ‘Supply Chain Management’. This system helps determine the exact timing required to complete the entire production, from processing of the raw material to actual merchandise delivery to customers. To achieve this, each work unit would work closely and connect together to trim down the time required to finish production while improving the quality of operations.

Lean Manufacturing

The Oriental Garment Co., Ltd. incorporates Lean Manufacturing System into the production management, alongside the Supply Chain Management system in order to cut down the production period from 150 days to only 90 days. This system not only equips the company with a more efficient product processing but also ensures a quick response service, thereby offering the best for customers.

Quality Assurance

With regards to quality assurance, the Oriental Garment Co., Ltd. has stepped into the future era of QA to emphasize on quality-ensured training. The company is one of the few that were trained directly by customers themselves as our certified QA staff conducts the QA process for the client, thereby eliminating the need for some order independent merchandise inspectors. This is routinely done to ensure that all products are manufactured with high standards and in consistent with customers’ preferences and specifications.

Six Sigma

The Six Sigma quality control system greatly helps the Oriental Garment Co., Ltd. to reach the leading spot in the garment export manufacturing industry. Each production stage is systematically monitored while the operating efficiency is enhanced.

Strategic Partner

Having an efficient operational and production management, a brilliant team of experts, high technology equipments, and a great mutual relationship between the company and its clientele, the Oriental Garment Co., Ltd. has no doubt earned the trust of all its trading partners worldwide, potentiating a special business alliance in the long run. In addition, the company was also chosen as the principal supplier to several world-renowned brands.

Business Process Re-Engineering

The Oriental Garment Co.,Ltd. performs an analysis and design of workflows and processes within the firm. A business process is a set of logically related tasks performed to achieve a defined business outcome. Re-engineering is the basis for many recent developments in management.

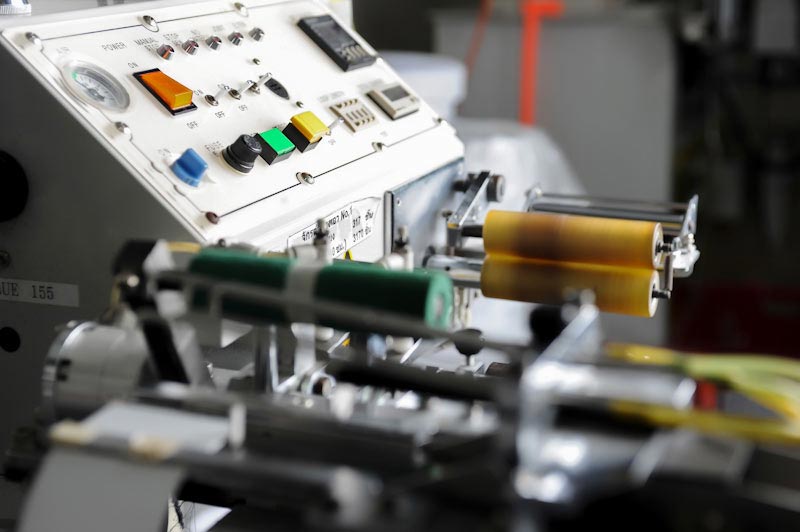

Statistical Process Control (SPC)

The Oriental Garment Co.,Ltd. employs the method of quality control which uses statistical methods. SPC is applied in order to monitor and control a process. Monitoring and controlling the process ensures that it operates at its full potential. At its full potential, the process can make as much conforming product as possible with a minimum (if not an elimination) of waste (rework or trash). SPC can be applied to any process where the “conforming product” (product meeting specifications) output can be measured. Some key tools are used in SPC. These include control charts; a focus on continuous improvement; and the design of experiments. An example of a process where SPC is applied is in our very company.

Total Productive Maintenance (TPM)

The Oriental Garment Co.,Ltd .practices the method for improved machine availability through better utilization of maintenance and production resources.Whereas in most production settings the operator is not viewed as a member of the maintenance team, in TPM the machine operator is trained to perform many of the day-to-day tasks of simple maintenance and fault-finding. Teams are created that include a technical expert (often an engineer or maintenance technician) as well as operators. In this setting the operators are enabled to understand the machinery and identify potential problems, righting them before they can impact production and by so doing, decrease downtime and reduce costs of production we can minimize the unexpected failure of the equipment or machine.